Painting Primers for Scenery Onstage and in the Studio - Order Today and Save! FoamCoat is flame retardant and water resistant. An ideal substitute for joint compound or plaster, it is water-based and non-toxic. It dries to a flexible, milky matte finish, and can be tinted or painte sanded and carved. Its 1 acrylic formulation provides excellent adhesion to a wide variety of substrates.

FlexCoat contains no plasticizers, so will not become brittle with age or exterior exposure. It provides a har durable finish that resists chipping and cracking, yet can be sanded smooth or carved to add detailing. Apply thick with a trowel or thin with a paintbrush.

Sets up in only about minutes. Extend the drying time by adding up to latex paint with your water before mixing into the dry foam coat. After it drie he added two more, much thicker coats, which were sanded down.

Foamcoat is a non-toxic, water based coating for styrofoam and polystyrene foam , as well as other surfaces. It can also be used to seal primed woo concrete block, primed fiberglass, papier macirc;cheacute;, muslin and many other surfaces. For particularly difficult materials, lightly sand surface to give it more tooth before applying FOAMCOAT.

Those sample jars are still available for you to experiment with before your next project. Rosco Foamcoat , Gallon. CrystalGel is a non-toxic, water-based material which provides a clear, plastic-like coating on virtually any surface used in modern stagecraft. It air dries quickly - usually within hours - to a flexible, translucent surface. Foamcoat dries to a very hard durable coating that resists chipping and cracking, yet can be sanded smooth or carved with detailing.

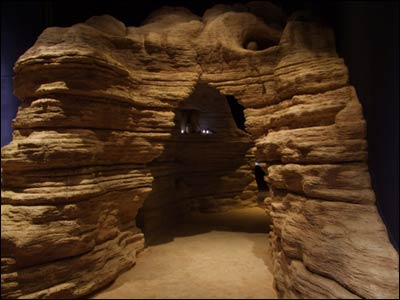

Free lighting advice and many items ship free! At the display company I’ve worked at in the past, we made a lot of sculpted pieces out of foam. Foamcoat goes on a little like joint compoun and creates a hard but flexible coating.

It can be sanded and painte but it doesn’t fall apart like joint compound. We have used many hard coating methods like plastic dips, resins, fiberglass, two part epoxies, and several other foam coating. Hot Wire Foam Factory 9views. Excellent for use as a protective coating for all types of foam projects. Especially useful on foam scenery or props that receive physical abuse or need to last for extended tours.

The coating can even. Stir well before use. Thinning is not recommended as it. Apply by brush, roller or airless sprayer. It is especially useful on. Surface Preparation:.

What began as seamless paper store has expanded to well over several thousand items that now supplies a wide range of industries like display and exhibition. All surfaces should. Flexcoat is a water-based coating for polyurethane foam , Styrofoam and ethafoam. Useful on foam scenery and props which must endure rough handling. When cure this clear finish provides long lasting durability, hardness and abrasion resistance in an environmentally safe, VOC compliant coating.

Mix in a clean container with clean water. Use part cool water per parts of powder (for example, cup of water per cups of powder). Add water to powder and mix until Foam Coat turns to a smooth paste. Add more powder or water as needed for your application.

A drier mix is stronger.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.