Affordable color ed concrete. How to dye concrete? Why to use color hardener instead of Integral color? What is a surface hardener?

To develop the proper bond and sufficient density, the moisture for wetting the hardener must come from the concrete substrate. The powdered color hardener is broadcast onto the surface, given time to absorb moisture, and is then floated into the concrete. It will actually strengthen slab surface by making it denser. COLOR HARDENER is a ready-to-use surface hardener for coloring and hardening freshly poured concrete.

It is typically used to provide the base color for stamped concrete. It is used for coloring and hardening freshly placed concrete flat work to produce an aesthetically pleasing pavement with a surface that is substantially harder and more wear-resistant than regular concrete. Initial Placement: Sprea shovel, ro and vibrate the initial concrete placement to eliminate voids and properly.

Pause for Initial Set: Allow concrete to initially set. When all visible bleed water has reabsorbed into the concrete. Broadcast of Hardener. Best Seller Quikrete oz. Step 1: Enter Your Zip Code.

Dry-shake color hardeners come as powders that are hand broadcast onto the freshly placed concrete and then worked into the surface with a float or trowel. Color Hardener Specifications. The most common pigments are iron oxides. In order to develop proper bond and adequate density, the moisture for wet- ting the hardener must come from the concrete substrate. Its superior concrete stamping and coloring characteristics make it ideal for use on many different commercial, industrial and residential colored concrete finishes.

When properly applied and troweled into newly place fresh concrete , it forms a colored concrete surface that is resistant to weathering, wear and normal abrasion. Suitable for interior and exterior use. When applie a dense layer is forme making the concrete surface more abrasion and impact resistant.

When contractors need a tough, easy-to-repair coating on a concrete walkway or area, they start with color hardener which becomes a very har very wearable surface. Sika Decorative Concrete. Applied to fresh concrete, it will produce a colorful, wear resistant concrete surface.

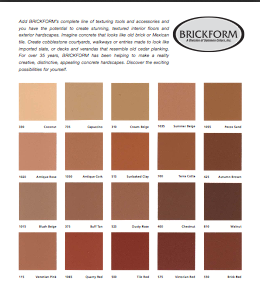

Using a mixture of light-fast color pigments, hard mineral aggregates, and Portland cement, this product creates a surface that is more wear resistant and less permeable to moisture and de-icing chemicals more so than standard concrete. It hardens and densifies, resulting in more durable and abrasion-resistant concrete surface. It is ideal for use with textured concrete, but is also excellent for standard troweled or broom—finished concrete, or for producing adjacent borders in contrasting colors.

A granolithic concrete material that is floated into fresh screed or concrete which colours, strengthens and creates durable surfaces for the concrete floors. It is a special blend of cement incorporating very hard-wearing aggregates, light fast pigments and additives which set rock-hard. With its strength, versatility and lifecycle cost advantages, concrete is the obvious solution to many building applications.

But plain concrete is like an empty canvas waiting for color. It will give a pigment rich color to concrete flatwork and precast panels, as well as increase resistance to abrasion and deicing salts. Timing is important for successful application of color hardener.

Normally, the concrete gets struck off, bull-floate and edged. When the concrete was days ol I treated part of it with a sodium-silicate hardener , applying two coats at a rate of about 3square feet per gallon, per coat. Two hours later I measured the floor’s wear resistance, making six tests on plain concrete and three on hardened concrete.

Concrete Stains and Sealers - Discounted and Shipped to You!

No comments:

Post a Comment

Note: only a member of this blog may post a comment.