No matter where they’re use they install quickly with little or no waste. Our manufacturing process creates uniform and predictable products, all with a limited lifetime warranty. Each veneer is graded ultrasonically so the veneer mix can be tailored to meet the required design characteristics.

This makes consistently straight and stable sections, virtually eliminating shrinkage and twist when used properly. LVL is always a major part of your materials cost for an addition, room bump-out, or wall elimination (for an open floor plan home). LVL beams are one of several different types of engineered lumber products on the market today.

Get the USA manufactured 2. Engineered Lumber for your building needs. Manufactured in the USA from Douglas fir. E LVL with Watershed Overview Remember to choose the 2. Paint to match decor. During the design process, many factors are considered when determining the size of a beam. WSO is used to reduce moisture related cupping, swelling and surface mold growth.

Shop lvl and a variety of building supplies products online at Lowes. Microllam LVL Beams are our most versatile solution. LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter and more uniform. LVL is similar in appearance to plywood without cross bands. By clicking I AGREE below, you are giving your consent for us to set cookies.

Moreover, installation is quick with very little or no waste. LVL is not suitable for the pressure treatment process due to material density and glue lines. Find submittal-ready datasheets, SDS, specs, ICC-ES reports. The products in this guide are readily available through our nationwide network of distributors and dealers.

In addition we allow resawing of Parallam PSL and Timberstrand LSL to a thickness of 1. Parallam Plus PSL may not be resawn and must maintain its original cross section. Please refer to Technical Bulletin 3for further information. Having the grain of all veneers run in the same longitudinal direction in a product that is strong when edge loaded as a beam or face loaded as a plank. Laminated veneer lumber ( LVL ) is manufactured by bonding layers of wood veneers together under heat and pressure using a waterproof adhesive. Calculate the size needed for a beam, girder, or header made from No.

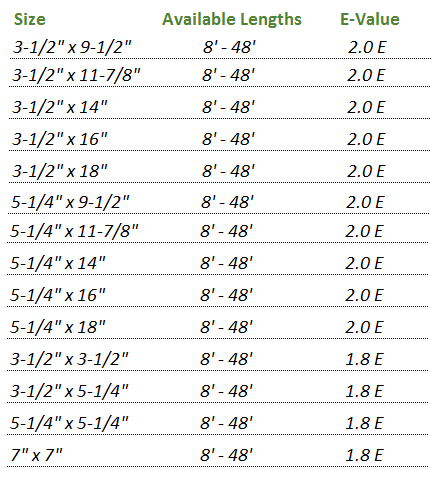

Covers any span and every load with pin point accuracy. They will not twist, bow, or cup. Versa Lam Laminated Veneer Lumber. E Value for longer spans. MICROLLAM LVL BEAMS.

The outside perimeter beam of this detail is LVL , there is quite a bit of it, I would guess around 1lineal feet or more, 2-plys. It is very well protected. It helps resist the effects of moisture on structural performance. Les poutres et les linteaux 2. Typically, LVL comes ¾” thick and ranges in depth from ¼” up to 18″.

To fine-tune the load-carrying potential of a LVL beam, just add another ply to the side of a beam. It takes time to laminate multiple layers of LVL.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.