Browse Our Variety Of Insulation —Great Deals On Quality Products. Find The Right Material For Every Job. It has high water resistance and R–value of 5. Fencing For Any Look. Kingspan GreenGuard Type IV XPS Insulation Board comprises closed–cell extruded polystyrene (XPS) with a minimum compressive strength of psi. It is available in a square edge boar ship–lap edge board and a score board.

It is produced from general purpose polystyrene by the process of extrusion. Download Brochure PDF? Globally XPS has been widely used for thermal insulation since the last years. These extruded sheets have a closed-cell structure and virtually no air-voids in between the cells. When using rigid Insulation in residential and commercial properties the most common boards used would be Polyiso (polyisocyanurate), EPS or XPS.

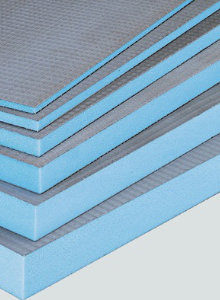

Quick Low-Cost Shipping, Anywhere! Extruded polystyrene ( XPS ) foam is a rigid insulation that’s also formed with polystyrene polymer, but manufactured using an extrusion process, and is often manufactured with a distinctive color to identify product brand. Each type of insulation board are very different and carry different R-values and compressive strength. Thermal Insulation for pipes, ducts and equipment. DOW Styrofoam Insulation - Blue Board.

Free 2-day Shipping On Millions of Items. Create Memories All Summer Long. It is recyclable and lightweight, and it is easy to handle and install. It is used in both residential and commercial construction in any climate across the United States. Input project size, product quality and labor type to get XPS Insulation material pricing and installation cost estimates.

Free, online XPS Insulation cost guide breaks down fair prices in your area. It is usually blue or pink in color, with a smooth plastic surface. Its extruded polystyrene (XPS) construction provides superior moisture resistance. And since it does not absorb moisture, it retains its insulating properties over time.

Extruded Polystyrene Insulation (XPS ) is a high-performance, closed-cell rigid insulation. With an R-Value of 5. Plus it’s lightweight, easy to handle, and easy to cut with a knife. For a list of complete adhesives for all applications from Dow, browse through our adhesives solutions. Choose rigid insulation wisely, and consider the effect its characteristics will have on the performance of the your project, overall product cost, and the best way to get the bang for your buck.

XPS is available as unfaced or paired with a number of various plastic facings. XPS products are manufactured in proprietary processes that melt plastic resin and additives into a molten material, which is extruded through a die where it expands and cools into a uniform closed cell rigid board with no voids or pathways for moisture to enter. Rigid-foam insulation packs a lot of R-value into a thin package, but not all rigid foam performs the same. The cost of this R-per inch valued insulation material is quite affordable (approximately 42¢ per sq. ft. for a 1-in.-thick 4×panel). It is composed of closed-cell foam and is mainly used as thermal insulation for foundation systems, inverted roofs (including roof terraces and green roofs) and parking lots made with SOPREMA products.

When it comes to concrete and insulation , contractors tend to be most familiar with extruded polystyrene ( XPS ). SOPRA- XPS is a rigid extruded polystyrene thermal insulating board with shiplap or squared edges on its four sides. XPS insulation is manufactured in a variety of board sizes with square and tapered edges. For use as general purpose insulation for roofing, wall and foundation applications. Tapered edge units are manufactured for the use in roofing applications, where the insulation is used to create slope for positive drainage.

Yet, expanded polystyrene (EPS) performs as well or better than XPS , and at a substantially lower cost.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.