Check the boards against each other. Choose their best looking sides, figure,. Step 3: Glue the Base to the. It seems the plans I used for my inspiration are no longer available. I sat down and drew out my loom.

The loom was two-side but the second side was not removable, which makes it harder to use. Also, the tension adjustment left much to be desired. So, when I was able to buy one of a better design, I did. Welcome to beginning inkle weaving.

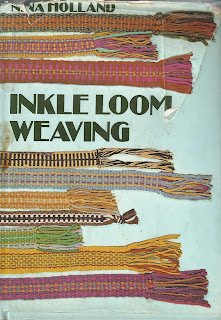

I will guide you through the process of basic plain-weave inkle weaving, starting with the design process and ending with simple finishing techniques. My directions and illustrations apply to the table style of inkle loom , but we can also address your custom or floor loom in class. They’re perfect for start-up weaving programs because they require little additional equipment, are easy to use and understan and are easily stored.

Our inkle loom is built with years of heavy use in mind. It has one open side for easy warping. The tension bar has a knob that adjusts warp. Peg Looms : How to build a peg loom and make rag rugs. Frame Looms : How to Buil Warp, and Weave on a Simple Frame Loom.

Backstrap Looms : backstrap loom. A Nylon furniture foot pad with screw. Inkle Looms : Inkle Loom Plans. A packet of white epoxy. Dremel Ultra saw for cutting plywood.

You can sew them together and make bags, placemats, cushion covers and much more. There are yards of ribbon on the loom in this picture. The inkle loom is capable of creat- ing two sheds, or openings, between the warp ends. To weave you will pass the weft yarn through first one and then the other of these two sheds.

You will first make a heading to prac- tice making the sheds and to prepare your warp for weaving the actual inkle band. The red lines show the path your warp threads will take on your loom, with one thread passing through a white heddle. Tension Bar Top left peg “Open” warp Top right peg “Heddle” warp Warp threads Heddle Heddle peg Warping pegs.

The ¾ pegs are pressed and glued into deep holes to withstand the tension typical of an inkle loom. The term “ inkle ” is defined as a colored tape or braid woven on a narrow loom and dates back to the th century. Get Your Build A Weaving Loom Today! Bay Is Here For You with Money Back Guarantee and Easy Return.

Looking For Build A Weaving Loom ? We Have Almost Everything on eBay. Make some string heddles. When you weave, the warp threads go up and down, and the weft threads go side-to-side, over. Now you are ready to warp your loom , which means putting the long up-and-down threads on it, ready to.

You are now ready to begin. Floor Loom Plans Free downloadable pdf file for building a inch floor loom. Archie Brennan Copper Pipe Tapestry Loom Plans.

You thread the warp onto the inkle loom in a continuous loop. Begin at the front peg, and bring the warp thread all the way along the bottom and around the backmost peg. Next, wind the warp back and forth between the pegs along the bottom of the loom and the back upright, moving upward from the back bottom corner peg. Also, I didn’t glue in the pegs as I plan on traveling with the loom soon.

A full-sized one is generally easier to use and you can create a wider range of things on it.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.