Fencing For Any Look. Create Memories All Summer Long. Rigid Styrofoam thick is not going to give you the R value that of fiberglass insulation has = R 19. However it will look a little better.

Also have them get a box of inch drywall or decking screws. You will have a lot of. What is the best way to cut foam boards? How to use a foam cutter? Measure your cut with a straightedge ruler.

Mark your cutting line on the foam with a permanent marker. Place your straightedge ruler on the rigid foam. Lay the rigid foam insulation on a flat. Step - Prepare to Cut. Next, take your long straightedge and line it up with your cutting lines.

Amazon link to Great products that every DIYer and Handyman should know about. This way, you can vacuum the fine foam created by the fine teeth more easily. Mark the foam sheet with a permanent marker following a straightedge. Lay a foam sheet with your measured cut line barely over the side of a work table. Hold the insulation steady on the.

As Chuck Miller demonstrates in this gem from the Fine Homebuilding Video Vault, a 3-in. For more information on working with rigid insulation , try these links: Choosing the Right Thickness of Exterior Foam Does Rigid Foam Insulation Trap Moisture in the Walls? There’s a Better Way: Cutting Rigid Insulation By Chuck Miller When Chris Ellis of Brewster, Mass. There are several ways to cut ridged insulation , depending on the thickness. I have found with thicker boards you can actually use a circular saw.

To attach the insulation , you can use screws with large washers, a special adhesive made for adhering foam board insulation or, for smaller pieces, you can seal them in with caulk or spray foam. In this video, Chuck Miller of Brewster, Mass. Included are other tips for working with rigid - foam insulation. Rolls of fiberglass insulation can be sliced with a utility knife and a straight edge, while foam board can be scored and snapped.

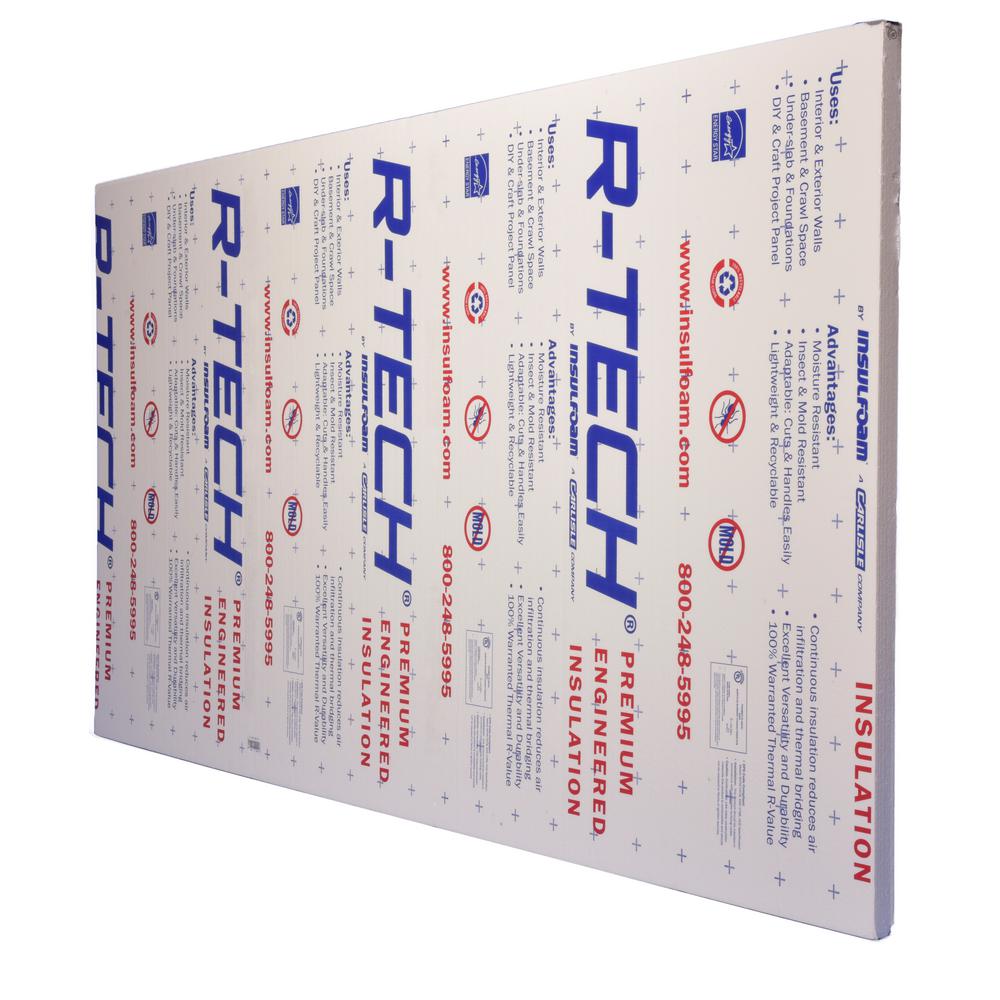

Rigid foam insulation is lightweight and relatively simple to cut. Friction holds cut sections of the panels in place between rafters or wall studs, but the foam board is also suitable for. Use a straight edge or T-square to guide your cuts.

Re: Best way to cut rigid foam board? Install the Rigid Foam Insulation Place each rigid foam sheet in its own wall bay. Cut the rigid foam with an ordinary wood saw. The fit should be firm but not so firm that the edges of the foam begin to tear. Serrated blades are great for cutting thick foam.

If you are cutting inches thick or less try an Olfa L-utility knife. Good clean accurate cuts. Instea you should keep the sheets of foam intact and install the foam as a continuous layer on the exterior side of your wall sheathing.

That way, the foam will interrupt thermal bridging through the studs. Foam insulation board is made out of coagulated foam and carries the appearance of condensed plywood. Available in a variety of colors, it is a widely used material in the home, visible on ceilings and walls in its capacity as an insulator. Draw a pencil line on the foam at that point. Place a straight edge on the line, and hold it firmly in place.

Cut panels to fit using a box cutter or snap-away utility knife. Position the first foam panel perpendicular to the wall or ceiling framing. Foam board insulation is commonly placed against the steel building siding, between the girts of exterior walls. To prevent air infiltration, place rigid insulation boards tightly together and seal the seams with tape or caulk.

This practice may worry some in cold climates since the foam board may act as a second vapor diffusion retarder. But mold and mildew can still grow on the surface of rigid foam insulation. The difference is that mold and mildew cannot enter rigid foam.

Look for blades that have a ceramic coating on them, as this coating will actually help to reduce the friction between the blade and the foam. In turn, this will reduce the amount of effort and force that is needed to push the blade through the foam to make the necessary cuts. If neede it can also be glued to surfaces with caulk, panel adhesive or.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.