Does hardiplank require caulk at the joints? What is hardiplank siding? Some local building codes may require different size flashing. Joint-flashing material must be durable, waterproof material that does not react with cement based products. Pattern Name: aluminum butt-joint flashing.

DESIGN FEATURES: Use to reduce moisture penetration behind the joint where two planks butt together and drain water over the top edge of the last full course of siding. Pre-cut for quick and easy installation. Coating eliminates any reaction with fiber cement. Joint Flashing Sheets Pair the Bear with James Hardie.

Here’s why: Peel and Stick: Sheets are pre-cut with a stick-it adhesive for the fastest application possible. Quick and Easy to Apply: Flash your butt joints in a Flash! Portable: Clips to Belt or. The product is a proprietary plastic, 20-year UV-rated sheet ml thick that is basically a six by twelve post-it note. Each sheet is pre-cut with a stick-it adhesive for the fastest application available.

Product description Bear Skin is a durable, non-corrosive flashing material used to prevent water and wind-driven rain from infiltrating the butt joints of lap siding. However, some local building codes may require different size flashing. James Hardie recommends 6-inch-wide flashing that overlaps the course below by 1-inch. The horizontal joints created between panels must be flashed properly to minimize water penetration. Treat horizontal panel joints by using one of the following methods: 1. After installing the lower course of panel siding , install vinyl or coated aluminum “Z” flashing at the top edge of the panel.

This is a 6” wide piece of weather resistive material to make sure that no water gets through. HardiPlank Lap Siding is a fiber cement siding product that looks like wood clapboards but outperforms it when it comes to weather resistance and. Deterioration of the caulking in the joint has become a maintenance issue for home owners over time. Joint flashing is recommended for all hardie lap siding now.

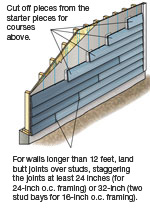

Vertical joints may be covered with wood or fiber-cement batten strips. Batten strips should span the vertical joint by at least ¾ in. Metal or PVC “H” moldings can be used to join two sections of HardiePanel siding. Do not extend siding beyond the required grade clearances. TIP: For Sierra panels, double studs at each panel joint allows fasten-ers to be placed outside of panel grooves.

Hardie does not recommend caulking the butt- joint on the color-plus siding ! If you’re going to use a butt- joint flashing , why not use the one that actually works:The ProLine Plank Flashing from Tamlyn. Best practices solution tested and proven to reduce moisture penetration behind the joint where two planks butt together and drain water over the top edge of the last full course of siding. Patented design allows for quick and easy installation. These days, most manufacturers have come out with recommendations when new siding is installe most of which require flashing behind those joints in order to maintain a warranty. I was thinking of using caulk to seal these joint , but realized that the gaps are quite large.

Do I need to seal edges at a butt joint ? If you are using primed siding , you must seal all exposed cuts of siding , including those at butt joints. Joint Cover corners come with nail holes on the lip for bottom nailing, making these corners easier to replace if damaged. Pro Siding Accessories sells a wide variety of siding accessories, including outside corners, joint covers, junction flashing , off stud joiners, and self-aligning clips for the construction industry.

You are guaranteed quality workmanship, outstanding customer service, fast order processing, reliable durability and dependability.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.